Knit Denim Fabric Wholesale in Los Angeles — Complete Buying & Production Guide

- by Lucy Zhou

Introduction

Knit denim fabric is a versatile and comfortable alternative to traditional denim, blending the look and durability of denim with the softness and flexibility of knitwear. If you're looking to buy knit denim fabric wholesale in Los Angeles, you've come to the right place.

Whether you're designing a new collection for a fashion line, creating custom pieces for a boutique, or sourcing fabric for a larger production run, purchasing high-quality knit denim fabric in bulk is essential for meeting market demand, ensuring production efficiency, and delivering premium products to your customers.

Newasia Garment Co., Ltd. (INNBLAC) is a trusted wholesale supplier of top-tier knit denim fabric, offering a range of options from ready-to-ship bulk fabrics to full customization services. This allows you to create a unique fabric selection tailored to your brand's specific needs, with flexible minimum order quantities.

As a proud manufacturing partner for global brands like American Eagle Outfitters, Uniqlo, Gap, Zara, Levi's, and Lee, we guarantee that our knit denim fabric meets the highest industry standards for quality, ethical production, and reliable, on-time delivery. Whether you’re in Los Angeles or anywhere else, our fabrics ensure your creations are of exceptional quality and style.

What is Knit Denim Fabric?

Knit denim is a modern hybrid that combines the look and color of traditional denim with the comfort and stretch of knit construction. Unlike woven denim (which uses a twill weave), knit denim is made on circular or flat knitting machines, resulting in a fabric that is:

-

More flexible and stretch-recovery friendly

-

Softer and often lighter weight

-

Less prone to rigid creasing

-

Suitable for leggings, joggers, dresses, skirts, and casual tops

Common types include denim-look jersey, ponte denim, French terry with indigo dye, and knitted jacquard with denim patterns.

Why Brands & Makers Choose Knit Denim

Designers and brands increasingly opt for knit denim because it builds:

✔ Superior wearer comfort

✔ Stretch and recovery performance

✔ Versatility across ready-to-wear categories

✔ Higher perceived value

Common knit denim garments include:

-

Stretch jeans

-

Jeggings

-

Denim skirts and shorts

-

Denim dresses

-

Active/athleisure denim pieces

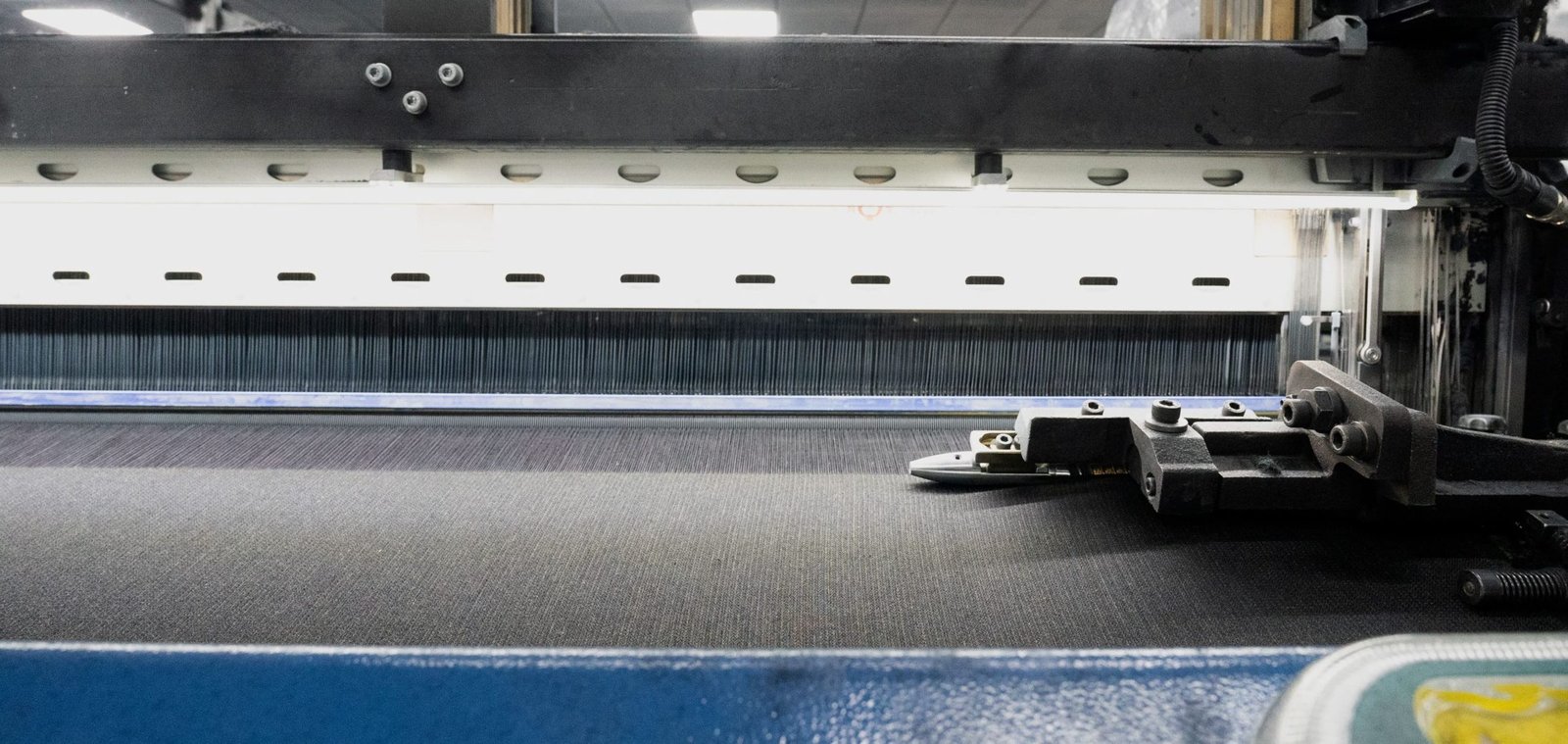

Impact of Manufacturing Process on Wholesale Knit Denim Fabric Quality

The manufacturing process plays a crucial role in determining the quality of wholesale denim fabric. Various factors, including the use of high-quality raw materials, the expertise of the manufacturers, and adherence to quality control measures, significantly impact the final fabric’s characteristics.

- Raw material quality: The quality of the cotton used in denim manufacturing has a direct influence on the fabric’s durability, softness, and color retention. Choosing cotton that is free from impurities and grown using sustainable practices ensures a higher-quality end product.

- Weaving techniques: The weaving process affects the fabric’s strength, weight, and texture. Well-executed weaving techniques, such as tight and consistent weaving, contribute to a more durable and desirable denim fabric.

- Dyeing techniques: The dyeing process determines the colorfastness and appearance of the denim fabric. Proper dye penetration and even distribution of the dye ensure a uniform and fade-resistant color. Advanced dyeing techniques, such as laser fading or eco-friendly dyeing methods, can enhance the fabric’s visual appeal while minimizing environmental impact.

Examples of Advanced Techniques Used in Denim Fabric Production

- Laser fading and distressing: Laser technology is often utilized to achieve faded or distressed effects on denim fabric, without the need for harsh chemical treatments or excessive washing. Laser fading provides precise fade patterns, resulting in a more customized and controlled distressed look.

- Eco-friendly dyeing: Sustainable dyeing methods have gained prominence in the denim industry. Techniques like zero-liquid discharge systems, where water and chemicals used in the dyeing process are recycled, minimize waste and environmental impact. Additionally, natural dyeing processes using plant-based dyes are gaining popularity as an eco-friendly alternative.

- Advanced finishing treatments: Denim fabric can undergo various finishing treatments, such as enzyme washing, stone washing, or resin coating, to achieve specific textures or effects. These treatments enhance the fabric’s softness, vintage appeal, or resistance to wrinkling.

What to Look for When Sourcing Knit Denim Wholesale

-

Fiber Content

-

Cotton-rich blends for breathability

-

Polyester blends for durability and moisture-wicking

-

Spandex/Lycra content (5-15%) for stretch and recovery

-

-

Weight & GSM

-

Lightweight (180-220 GSM): for tops, dresses

-

Medium weight (220-300 GSM): for skirts, joggers

-

Heavyweight (300+ GSM): for structured knit denim jackets, pants

-

-

Finish & Wash

-

Indigo-dyed knit denim

-

Washed/garment-dyed for vintage look

-

Brushed interior for extra softness (brushed knit denim)

-

-

Minimum Order Quantity (MOQ)

-

LA wholesalers typically offer 10-50 yards per color/style for sampling.

-

Full bolt MOQs vary; some allow split bolts for emerging designers.

-

-

Certifications

-

Oeko-Tex, GRS (Global Recycled Standard), organic cotton certificates if sustainability is a priority.

-

Sourcing Knit Denim Fabric in Los Angeles — Local Options

Los Angeles is one of the largest apparel and fabric hubs in the U.S., with multiple textile districts and wholesale markets.

Pros of LA sourcing:

-

Immediate access to stock

-

No import lead times

-

Easy inspection before commitment

-

Strong fashion industry ecosystem

Cons:

-

Higher unit cost compared to imported fabric

-

Limited mill runs compared to large Asian suppliers

-

Smaller volume capacities

Common LA fabric suppliers may stock basic knit denim widths and weights, but variety and specialization can be limited.

Overseas Sourcing (China/Asia) — Cost & Quality Comparison

Asia remains the global hub for textile mills and fabric production — especially China, with advanced preshrunk knit denim runs and specialized finishing capabilities.

Cost Comparison

| Source | Avg Unit Cost | Lead Time | MOQ | Variety |

|---|---|---|---|---|

| LA Local Supplier | High | Immediate | Low | Medium |

| China/Asia Mill | Lower | 30–45 days | Medium | High |

Advantages of international sourcing:

-

Lower cost per yard

-

Richer fabric variation

-

Greater control over GSM & fiber blends

-

Advanced finishing (enzyme, softener, wash effects)

Challenges:

-

Longer lead times

-

Duty/tariff considerations

-

Need for quality assurance systems

One-Stop Fabric and Apparel Manufacturing Partner

For over 39 years, LY Denim has been a trusted leader in providing high-quality denim fabrics and custom garment solutions. We have combined advanced production technology with an expert team to deliver tailored customized clothing with an annual capacity exceeding 30 million , ensuring we meet the evolving demands of global clients

|

6+ Professional factories |

30 million + Annual production capacity

|

Customization Professional design and production |

Garment Deliver with peace of mind |

5 Key Cores about Us - One-Stop Customization Solution.

|

30 million annually output

|

80% in-stock fabrics

|

Custom Fabric & Garment

|

Innovation

|

Quality is Priority Quality fully checked from beginning to end. |

Custom From Idea to Fabric, Unique and Competitive

With our complete range of customization options at your disposal, we help you make unique woven denim fabric that meets your market’s sophisticated demands.

ColorWidth |

Slub Style

Weight |

TextureElasticity |

Touch FeelShrinkage |

Fabric WholesalerWith fast and seamless access to woven denim fabrics, wholesalers can grow their customer base and strengthen their brand identity.

|

Garment Factory (Own Brand/OEM/ODM)We provide a wide range of fabric options, from classic essentials to luxurious and stylish designs, all backed by our rigorous quality control system to ensure consistent premium quality from yarn to finished fabric.

|

Unmatched Quality Control Every Step of the Way

We perform comprehensive quality inspections to ensure the superior performance of our woven denim fabrics.

- Yarn Test

- Fabric Inspection

- Dyeing Color Test

- Finishing Test

Why Choose Us

Independent baseWe have our own laboratory and can independently develop fabrics , China Professional certificationCertification: ISO 9001, ISO 14001,BSCI,GRS |

Full-equippedFull-equipped, from fiber manufacturing, yarn spinning, weaving, dyeing and processing to finished product production

Rich experienceProfessional, large and experienced design team, combined with the latest artificial intelligence technology |

Our Facilities12,000 skilled employees, daily production capacity exceeds 100,000 pieces |

Trusted by Global Clients

|

|

|

|

|

|

|

Our Process Setup is Optimized for Mass Production

|

Step 1

Step 4 |

Step 2

Step 5 |

Step 3

Step 6 |

Certified Professional Clothing Producer

We are very proud of these certificates! They represent Newasia Garment Co.,Ltd. (INNBLAC) ’s amazing achievements and accreditations. They show how much we care about quality, safety, and professionalism.

We’re proud to say that we have obtained BSCI and ISO 90001 certificates, and inspection certificates for filling materials such as down and cotton. We follow international standards throughout our production process and take responsibility for the quality of our products.

As one of China’s leading clothing manufacturers, we are pleased to be recognized by respected organizations. These certifications underscore our reliability as a trusted supplier to the global apparel industry.

Trusted Certificates:

| |

|

|

|

|

|

|

FAQ — Knit Denim Fabric Wholesale & Manufacturing

Q: What is knit denim used for?

Knit denim is used for stretch jeans, jeggings, skirts, dresses, and comfortable denim-style garments.

Q: Can I get custom fabric blends?

Yes — Newasia can help develop custom blend formulations to meet specific weight, stretch, or functional requirements.

Q: How does overseas sourcing compare cost-wise to LA?

Overseas fabric sourcing typically yields lower cost per yard, wider variety, and production flexibility, though lead times are longer.

Q: Is quality consistent with overseas mills?

With proper pre-production testing and QC processes, yes — consistent high quality is achievable.

Conclusion

Los Angeles remains a prime destination for sourcing knit denim fabric wholesale, offering everything from stock options to custom developments. Whether you're producing high-fashion knit denim separates or comfortable denim-look athleisure, LA’s textile district provides the materials, expertise, and speed-to-market crucial for today’s fashion industry.

For brands looking to manufacture with knit denim fabrics, Newasia Garment Co., Ltd. has extensive experience handling knit denim constructions—from pattern-making suited for stretch fabrics to sewing techniques that maintain recovery and shape.

👉 Contact us today to request fabric swatches, pricing, and bespoke production planning.

services@innblac.com

services@innblac.com +8613802505081

+8613802505081