Denim Dyeing Process

- por {{ author }} Lucy Zhou

Introduction: The Art of Indigo in Denim Manufacturing

Denim isn’t just a fabric—it’s an icon. From rugged workwear to modern street fashion, the signature blue hue of denim owes its magic to one critical step in the manufacturing chain: the denim dyeing process.

At Newasia Garment Co.,Ltd. (INNBLAC) , we’ve spent over 39 years mastering denim dyeing and finishing. Our expertise blends traditional indigo techniques with modern, eco-conscious innovations, ensuring every yard of fabric achieves perfect depth, color fastness, and character.

In this article, we’ll explore how denim is dyed, the different dyeing methods used in the industry, and how Newasia Garment Co.,Ltd. (INNBLAC) ’s advanced dyeing systems deliver vibrant, sustainable results trusted by leading brands worldwide.

What Is Denim Dyeing?

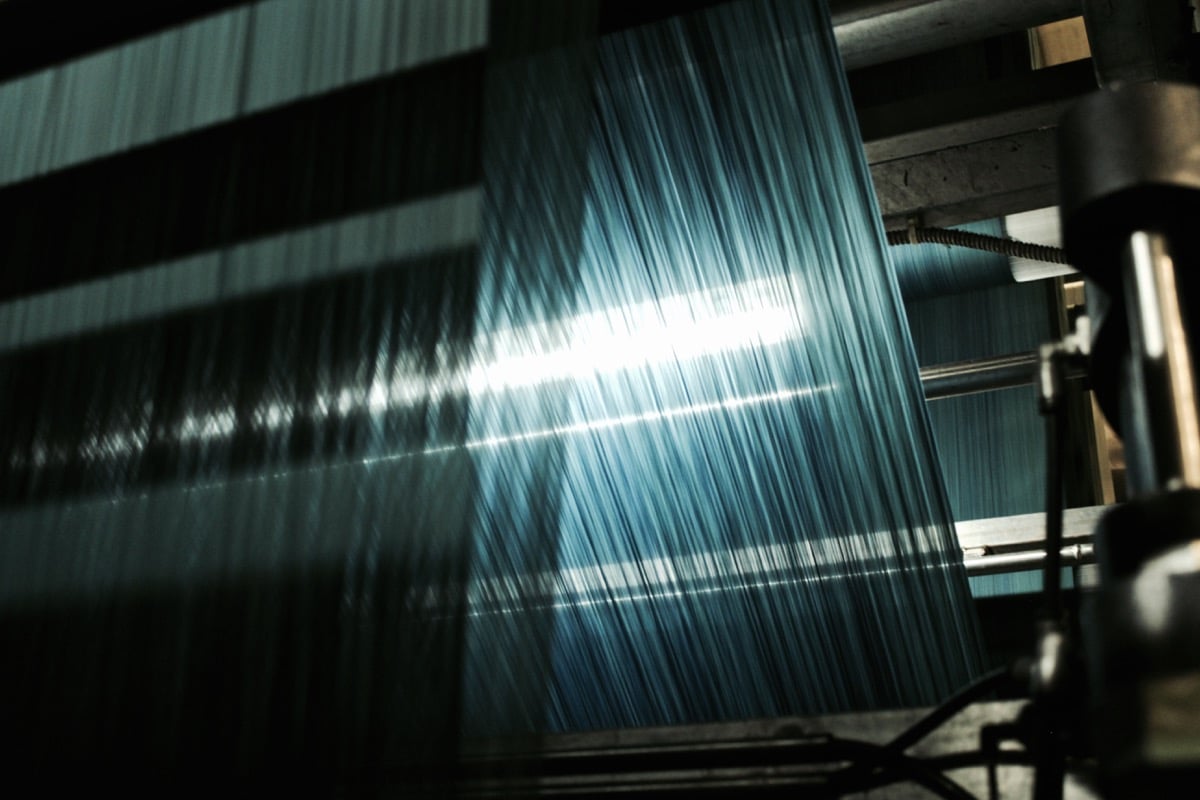

The denim dyeing process refers to coloring the yarns or fabric with indigo dye to achieve the classic blue shade associated with jeans. Unlike most fabrics, denim is dyed before weaving—typically only the warp yarns are dyed, while the weft yarns remain white. This combination gives denim its iconic blue face and white interior, as seen when jeans are distressed or faded.

Key Goals of Denim Dyeing

-

Achieve the rich, uneven indigo tone

-

Ensure strong color fastness and wash durability

-

Maintain fabric softness and flexibility

-

Reduce water and chemical use for sustainability

Types of Dyes

-

Natural Dyes: Sourced from plants, minerals, or insects (e.g., indigo, henna). Offer subtle, earthy tones.

-

Synthetic Dyes: Chemically derived, introduced in the 19th century. Provide vibrant colors and cost efficiency.

Denim-Specific Dyeing Methods

Denim is commonly dyed with indigo using techniques such as:

-

Rope Dyeing – Yarns are dyed in rope form for classic vintage fading

-

Slasher Dyeing – Continuous sheet dyeing for uniform color

-

Garment Dyeing – Finished garments are dyed for a soft, lived-in look

These methods help create denim’s signature appearance and fading behavior, balancing aesthetics, durability, and production efficiency.

Importance of Denim Dyeing in the Fashion Industry

Denim dominates wardrobes worldwide, with global production exceeding 6 billion pairs annually. The denim dyeing process isn't just about color—it's the gateway to versatility, enabling trends from raw selvedge to distressed washes. For manufacturers like Newasia Garment Co.,Ltd. (INNBLAC) , precise dyeing ensures durability and aesthetic appeal, meeting consumer demands for ethical, high-performance fabrics in a $100B+ market.

Types of Denim Dyeing Methods

1. Rope Dyeing (Traditional Premium Method)

Rope dyeing is considered the gold standard for high-quality denim. In this process, multiple yarns are twisted into ropes and passed through indigo dye baths several times. Each dip allows oxidation, giving the indigo its signature blue tone while leaving the yarn’s core white—creating the “ring-dyed” effect that fades beautifully over time.

Advantages:

-

Rich, deep color with superior fading potential

-

Minimal yarn breakage

-

Long-lasting denim quality

At Newasia Garment Co., Ltd.(INNBLAC), we use automated rope dyeing machines capable of up to 12–15 dips per cycle, ensuring consistent penetration and color depth.

2. Slasher Dyeing (Efficient Continuous Process)

Slasher dyeing is a more modern, high-throughput method often used for mass denim production. Instead of ropes, yarn sheets are directly passed through several indigo baths and oxidation chambers.

Benefits:

-

High production efficiency

-

Ideal for medium-weight denim

-

Lower operational cost

Our slasher dyeing lines at Newasia Garment Co.,Ltd. (INNBLAC) are optimized for precision temperature control, dye bath consistency, and automatic tension balancing to maintain even coloration across thousands of meters.

3. Sulfur Dyeing (For Black or Colored Denim)

While indigo produces the classic blue, sulfur dyes are used for black, grey, brown, or olive denim. These dyes offer high color fastness and smooth tones.

We apply sulfur bottoming and topping techniques, allowing us to create dual-tone effects (e.g., blue-black or grey-blue) often seen in premium designer jeans.

4. Eco-Friendly and Sustainable Dyeing Innovations

Newasia Garment Co.,Ltd. (INNBLAC) invests heavily in green dyeing technology to reduce environmental impact.

Our sustainability practices include:

-

Ozone Dyeing: Uses ozone gas instead of water for oxidation—saving 60–70% of water.

-

Foam Dyeing: A waterless process that reduces chemical use by 90%.

-

Recycled Indigo: Reuses recovered indigo pigments from wastewater treatment.

-

Closed-loop systems: Capture and recycle 95% of water used in dyeing.

These innovations meet GRS, ISO, and BSCI certification standards.

Comparison of Denim Dyeing Methods: Rope Dyeing vs. Slasher Dyeing

| Feature | Rope Dyeing | Slasher Dyeing |

|---|---|---|

| Color Effect | Strong ring dye effect, ideal for vintage fading | Even coloring, suitable for solid tones |

| Production Capacity | Higher output, suitable for mass production | Lower minimums, flexible for small batches |

| Dye Penetration | Even and deep penetration, rich color fastness | Moderate penetration, uniform surface coloring |

| Yarn Suitability | Suitable for conventional and coarse yarns | Ideal for fine yarns, low tension process |

| Dye & Resource Use | Less dye and reducing agent, lower yarn waste | More flexible color options, usually lower energy use |

| Process Features | Requires rebeaming after dyeing | No rebeaming, simpler process flow |

| Color Consistency | High consistency, avoids center-side shade variation | Level coloring throughout the yarn sheet |

Summary:

Rope dyeing excels in producing high-quality vintage fades with better color consistency and depth, making it ideal for premium and mass-market denim. Slasher dyeing offers greater flexibility and efficiency for smaller batches and finer yarns, with advantages in energy use and process simplicity.

Step-by-Step Denim Dyeing Process at Newasia Garment Co., Ltd.

Here’s how your denim color journey unfolds inside our factory:

1. Yarn Preparation

High-quality cotton yarns are wound onto cones and combined into warp beams. Before dyeing, they undergo desizing, scouring, and bleaching to remove impurities and ensure even dye absorption.

2. Indigo Dye Bath Dipping

The yarn passes through multiple indigo dye baths—each dip adds a thin indigo layer to the surface. The yarn never absorbs color fully into the core, creating the signature “white core effect.”

3. Oxidation

After each dip, the yarn travels through an oxidation tower, where exposure to air converts indigo leuco dye to the insoluble blue form. This step is critical for color consistency.

4. Repetition & Layer Building

The dipping and oxidation cycle repeats 8–15 times, depending on the required shade intensity.

5. Washing & Drying

Residual chemicals are removed through soft washing before the yarns are dried under controlled heat conditions.

6. Sizing

A protective coating of starch and binders is applied to strengthen the yarns for weaving.

7. Weaving & Finishing

The dyed warp yarns are woven with undyed weft yarns, forming denim’s unique texture. Finishing processes—such as enzymatic washing, softening, and sanforization—ensure comfort and durability.

Sustainability: Our Commitment to Responsible Dyeing

At Newasia Garment Co., Ltd.(INNBLAC), sustainability isn’t a buzzword—it’s embedded in every process.

We proudly implement:

-

Low-liquor ratio dyeing systems to save water

-

Non-toxic, biodegradable dyes and auxiliaries

-

Solar-heated dye baths to reduce energy consumption

-

Effluent treatment plants (ETP) for wastewater recycling

Our Environmental Compliance Certifications:

-

BSCI Certified Factory

-

GRS (Global Recycle Standard)

-

OEKO-TEX® Standard 100

-

ISO14001 Environmental Management System

Why Leading Brands Trust Newasia Garment Co.,Ltd. (INNBLAC) for Denim Dyeing & Production

Over the past three decades, Newasia Garment Co., Ltd.(INNBLAC) has become a trusted OEM/ODM partner for global fashion leaders, including:

-

American Eagle Outfitters

-

Levi’s

-

Lee

-

Uniqlo

-

Gap

Our partners value our:

-

In-house indigo rope and slasher dyeing lines

-

Full vertical integration—from spinning to finishing

-

39+ years of denim R&D expertise

-

140+ production lines and 12,000 skilled workers

-

Daily output exceeding 100,000 pcs

Whether you’re building a premium denim collection or a sustainable fashion line, we tailor every production detail to your design intent.

Our OEM/ODM Services for Denim Brands

-

Custom denim design and development

-

Fabric sourcing and indigo shade matching

-

Sample development and fit approval

-

Eco-friendly washing and distressing (laser, enzyme, ozone)

-

Private label branding (tags, packaging, embroidery)

-

Global shipping and customs support

MOQ: 100 pcs per style | Lead time: 15–30 days | Worldwide delivery

FAQ – Denim Dyeing Process & Manufacturing

Q1: What type of dye is used for denim?

Mostly indigo dye, sometimes combined with sulfur dyes for black or colored denim.

Q2: What is the difference between rope dyeing and slasher dyeing?

Rope dyeing provides deeper, more natural fades for premium denim, while slasher dyeing is faster and more economical for high-volume production.

Q3: Is denim dyeing environmentally harmful?

Traditional dyeing can be resource-intensive, but Newasia Garment Co.,Ltd. (INNBLAC) ’s eco dyeing technology reduces water and chemical use by up to 80%, ensuring sustainability.

Q4: Do you offer custom indigo shade matching?

Yes! We can reproduce specific indigo tones or create custom colorways based on your brand’s requirements.

Q5: Can you produce denim for both men’s and women’s collections?

Absolutely. We specialize in men’s, women’s, plus-size, and sustainable denim lines—from skinny to wide-leg, skirts, and jackets.

Q6: What is your MOQ for denim jeans?

Our MOQ starts from 100 pieces per design. We also support small brands and startups.

Q7: Do you offer private label services?

Yes! We provide private label, custom branding, and packaging tailored to your needs.

Q8: Do you produce for well-known brands?

Yes, we are verified OEM partners of major international fashion brands, including Gap and American Eagle.

Q9: How long does it take to manufacture jeans?

Standard lead times range from 15–30 days, depending on order volume, wash complexity, and customization requirements. We also offer expedited production when needed.

Conclusion: Crafting the Future of Denim with Precision and Purpose

The denim dyeing process defines not only color but also the soul of every pair of jeans. At Newasia Garment Co., Ltd.(INNBLAC), our commitment to craftsmanship, technology, and sustainability ensures every denim product we make embodies durability, style, and responsibility.

From indigo baths to finished jeans, every stage reflects our mission to create premium, sustainable denim for global brands.

📞 Contact Newasia Garment Co.,Ltd. (INNBLAC) Today

Looking for a trusted partner with advanced denim dyeing capabilities?

We’re ready to bring your denim vision to life—from yarn to finished garment.

servicios@innblac.com

servicios@innblac.com +8613802505081

+8613802505081