When Are Denim Jeans Dyed During Manufacturing?

- por {{ author }} Lucy Zhou

Introduction

Understanding when denim is dyed in the manufacturing process is essential for brands, designers, and sourcing teams who want to produce high-quality jeans with consistent color, fade performance, and durability. Denim dyeing is one of the most important—and technically complex—steps in the entire production chain.

In this complete guide, we explain exactly when denim is dyed, how the process works, the differences between rope dyeing, slasher dyeing, and garment dyeing, and what high-quality dyeing looks like in a professional denim factory.

At the end of this guide, you will also learn why Newasia Garment Co.,Ltd. (INNBLAC)—a manufacturing partner of American Eagle Outfitters, Uniqlo, Gap, Levi’s, and Lee—is the ideal OEM manufacturer for brands seeking consistent, premium denim production.

Short Answer: Denim Jeans Are Dyed Before the Fabric Is Made

To answer the question directly:

👉 Denim is dyed at the yarn stage—after cotton fibers are spun into yarn, but before the fabric is woven.

👉 This step is called warp yarn dyeing, usually done by rope dyeing or slasher dyeing.

This is why denim has its signature look: the warp yarn is dyed indigo blue, while the weft yarn is left white.

The Basics of Overdyed Jeans

Overdyed jeans are characterized by a higher amount of dye than that of traditional jeans. They are still made of denim. All jeans, in fact, are made of denim. Overdyed jeans are simply made with more dye during production.

As previously mentioned, manufacturers rely on dye to give their jeans color. Denim is essentially cotton, and cotton is naturally white. Therefore, unless a pair of jeans is white, they must be dyed during production. Dyeing changes the color of jeans, thereby opening the doors to new possibilities. Manufacturers can create jeans in virtually any color by dyeing them. Jeans are available in indigo, light blue, red, yellow, green, black and countless other colors — all of which are dyed. The term “overdyed jeans” simply refers to jeans that contain a larger total volume of dye than standard or traditional jeans.

Full Breakdown: When Denim Is Dyed During Manufacturing

Below is the complete timeline of the denim manufacturing process, showing exactly where dyeing takes place.

1. Fiber Preparation → No Dyeing Yet

Cotton goes through:

-

Opening

-

Cleaning

-

Carding

-

Combing

-

Drawing

No dye is applied at this point.

2. Spinning → Still No Dyeing

Cotton fibers are spun into yarn:

-

Ring-spun

-

Open-end spun

-

Compact spun

These yarns are still undyed (natural white).

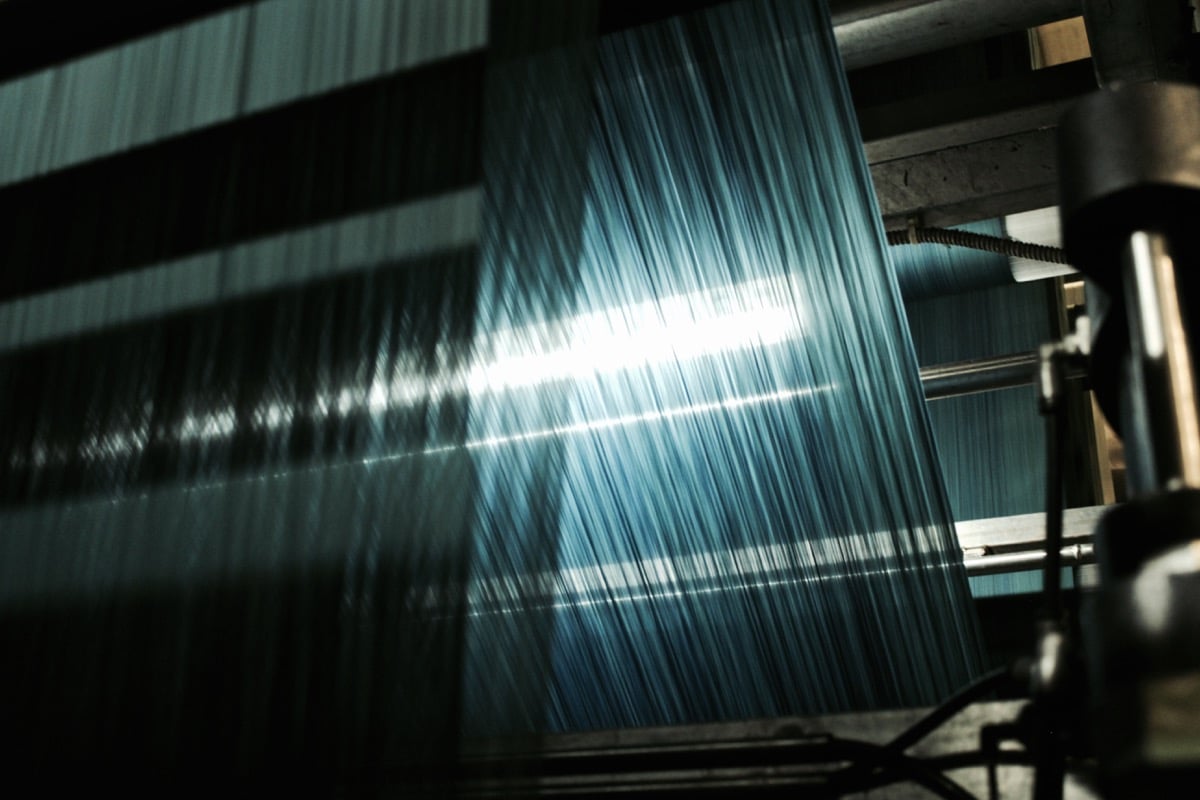

3. Yarn Dyeing — This Is When Denim Is Dyed

This is the key stage.

Denim’s color comes from dyeing the warp yarns before weaving. This is where the classic blue, black, or grey denim shade is created.

There are three primary dyeing methods:

● Rope Dyeing (Premium, Best Fading Effects)

Used by top-tier denim mills.

Process:

-

Yarn is collected into long ropes

-

Soaked in indigo solution multiple times

-

Oxidized between dips

-

Dyestuff settles only on the outer layer of the yarn

Characteristics:

-

Produces the richest, most authentic indigo color

-

Creates natural, vintage fading (because the yarn is “ring-dyed”)

-

Used for premium jeans and heritage denim

● Slasher Dyeing (Efficient for Large Production)

More automated and faster.

Process:

-

Yarns pass through multiple indigo baths in sheet form

-

Then sized and dried

-

Ideal for large orders and consistent production

Characteristics:

-

High efficiency

-

Uniform color consistency

-

Common for mid- to high-volume production

● Sulfur Dyeing (Used for Black & Grey Denim)

Used for:

-

Black denim

-

Charcoal denim

-

Colored denim

Sulfur dyeing can replace indigo or be combined with indigo to create rich tones.

4. Weaving (After Dyeing)

Once yarns are dyed:

-

Blue warp yarns

-

Undyed white weft yarns

…are woven together into denim’s signature 3×1 twill weave.

No dyeing occurs during weaving.

5. Fabric Finishing (No Dyeing)

The woven denim goes through:

-

Sanforization (pre-shrinking)

-

Setting and softening

-

Surface finishing

Still no dye is added.

6. Garment Making → Optional Dyeing / Overdyeing

After sewing, some jeans undergo additional color treatments, such as:

-

Overdye

-

Reactive dye

-

Pigment dye

-

Tinting

-

Enzyme fading

-

Laser finishing

These processes adjust the final appearance but are not the primary dye stage.

Dye is regularly used in the construction of jeans. When making their jeans, manufacturers bathe the raw denim material in a solution consisting of water and dye. The dye, of course, is responsible for giving jeans their color. Indigo jeans are bathed in indigo dye, whereas red jeans are bathed in red dye. Regardless, jeans receive their color from the dye to which they are exposed. You might be surprised to learn, however, that some jeans are overdyed during production.

Why Denim Is Dyed at the Yarn Stage: Key Reasons & Benefits

| Feature | Reason & Mechanism | Result & Advantage |

|---|---|---|

| "White-Core" Fading Effect | Indigo dye cannot fully penetrate cotton fibers | Creates unique, natural fading patterns over time |

| Fabric Strength Preservation | Yarns are dyed before weaving (warp-dyed) | Maintains structural integrity during production |

| Color Consistency | Centralized dyeing process before fabric formation | Ensures uniform color across large production batches |

| Versatile Fading Techniques | Surface dye layer over white core enables multiple treatments | Allows stone washing, sanding, whiskering, and laser fading |

Dyeing at the yarn stage is fundamental to achieving authentic denim characteristics and enabling the distinctive fading properties that make denim unique.

Types of Denim Dyeing and When They Occur

| Dyeing Method | When It Happens | Used For | Notes |

|---|---|---|---|

| Rope Dyeing | Before weaving | Premium denim | Best fading, rich color |

| Slasher Dyeing | Before weaving | Large-scale denim | Efficient & consistent |

| Sulfur Dyeing | Before weaving | Black/grey denim | Deep, even tones |

| Garment Dyeing | After sewing | Fashion denim | Soft, vintage look |

How High-Quality Manufacturers Ensure Dyeing Consistency

Top factories follow strict standards:

✔ AATCC colorfastness testing

-

Crocking

-

Wash fastness

-

Perspiration fastness

✔ Shade continuity check

Each dye lot must match approved lab dips.

✔ Temperature and pH control

Important for indigo stability.

✔ Automated dipping systems

Ensures uniform saturation.

✔ Fabric inspection before weaving

Avoids striping or shade variation.

This is how professional factories maintain premium quality—for both fast fashion and luxury denim brands.

Professional Denim Manufacturing at Newasia Garment Co.,Ltd. (INNBLAC)

Newasia is one of Asia’s leading OEM/ODM denim manufacturers, with advanced dyeing and finishing capabilities recognized by global brands.

We are a manufacturing partner of:

-

American Eagle Outfitters

-

Uniqlo

-

Gap

-

Levi’s

-

Lee

Our denim production system covers the full process:

- ✔ Rope dyeing & slasher dyeing

- ✔ Sulfur black and sulfur color dyeing

- ✔ Premium weaving partners

- ✔ Full washing lab: laser, enzyme, ozone, e-flow

- ✔ Strict shade control & AQL 2.5 QC

- ✔ Low MOQ for new brands (100 pcs)

- ✔ Advanced OEM customization

We handle everything from design to final garment finishing.

Why Brands Choose Newasia Garment Co.,Ltd. (INNBLAC) for Denim Dyeing & OEM Production

1. International Dyeing Standards

We follow AATCC and ISO colorfastness standards.

2. High Consistency Across Dye Lots

Strict color-management systems ensure uniform shades.

3. Full Production Transparency

From yarn selection to final washing.

4. Low MOQ + Stable Large-Scale Capacity

Suitable for small brands AND major retailers.

5. Trusted by World-Famous Brands

Our work meets global retail quality requirements.

FAQs About When Denim Is Dyed

Q1:Are jeans dyed before or after being sewn?

Mostly before—during the yarn dyeing stage.

Q2:Why are only the warp yarns dyed?

This creates denim’s iconic blue-and-white twill texture.

Q3:What dye is used for traditional blue jeans?

Indigo dye, either natural or synthetic.

Q4:Can jeans be dyed after sewing?

Yes—in overdye or garment dye processes.

Q5:Why does denim fade over time?

Indigo only coats the yarn surface, creating natural aging.

Shipping & Fulfillment

-

For in-stock items: ships worldwide within 3–7 days

-

For custom orders: production lead time 15–30 days

-

All shipments handled with full export documentation for smooth clearance

- Drop shipping available upon request

Work With Newasia for Custom OEM Denim Jeans Manufacturing

Newasia Garment Co.,Ltd. (INNBLAC) is ready to help brands, designers, and wholesalers create premium denim collections with professional dyeing, washing, and full-package OEM services.

📌 We are also a partner of American Eagle Outfitters, Uniqlo, Gap, Levi's, and Lee.

📌 For customized OEM services, please contact us.

👉 Request Samples & Pricing

👉 Start Your Denim Production Today

servicios@innblac.com

servicios@innblac.com +8613802505081

+8613802505081